Why Does a Well Designed Sheet Metal Shell Matter More Than You Think?

2026-01-04

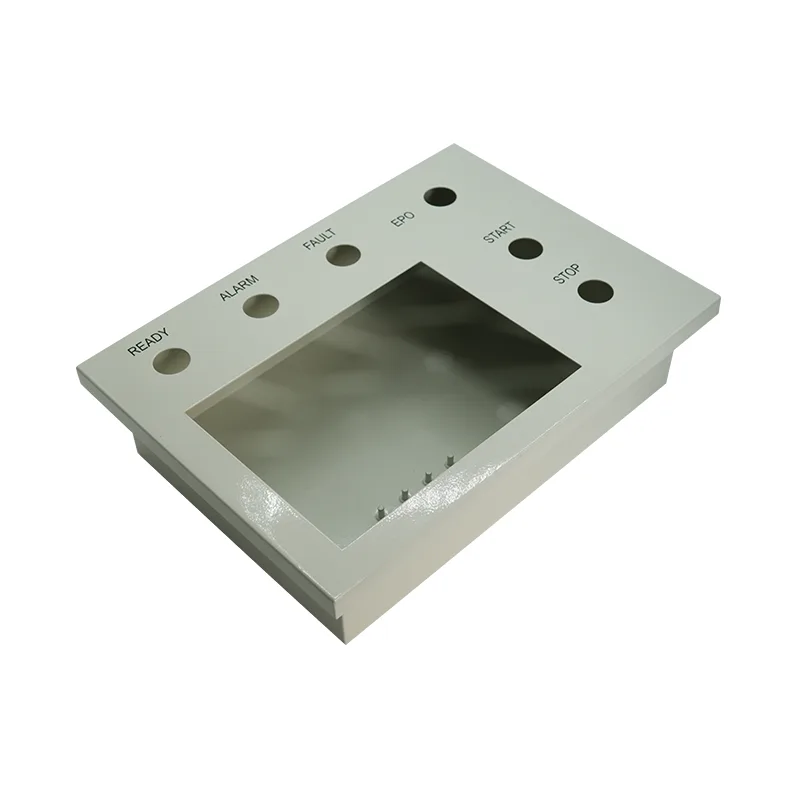

When I first started evaluating enclosure solutions for industrial and electronic equipment, I quickly realized that the housing itself often determines long term reliability. That was also when I came across Zhongyilong while researching practical applications of the Sheet Metal Shell. Instead of focusing only on appearance, the discussion naturally shifted toward durability, manufacturability, and real world performance.

What Problems Does a Sheet Metal Shell Actually Solve?

From my experience, clients rarely ask for a Sheet Metal Shell just for aesthetics. They are usually dealing with concrete issues such as heat buildup, electromagnetic interference, or structural instability. A properly engineered enclosure addresses these challenges at the source rather than relying on temporary fixes.

- Protects internal components from impact, dust, and moisture

- Improves heat dissipation through optimized metal thickness and venting

- Enhances EMI shielding for sensitive electronic systems

- Supports precise assembly and easier maintenance

How Does Material Choice Influence Sheet Metal Shell Performance?

One thing I always emphasize is that not all metals behave the same way. Selecting the right alloy for a Sheet Metal Shell directly affects strength, corrosion resistance, and cost efficiency. Aluminum, stainless steel, and galvanized steel each serve different operational needs.

| Material Type | Key Advantage | Typical Application |

|---|---|---|

| Aluminum | Lightweight and corrosion resistant | Electronic housings and communication devices |

| Stainless Steel | High strength and durability | Harsh industrial environments |

| Galvanized Steel | Cost effective with surface protection | General purpose enclosures |

Why Does Precision Manufacturing Matter for a Sheet Metal Shell?

I have seen many projects fail simply because tolerances were ignored. A Sheet Metal Shell must align perfectly with internal components, mounting points, and external interfaces. Precision cutting, bending, and welding ensure that the enclosure performs as intended over years of operation.

- Consistent dimensions improve assembly efficiency

- Accurate bending reduces stress points

- Clean surface finishing supports coating and branding

Can Customization Improve the Value of a Sheet Metal Shell?

In real projects, standard designs rarely meet all requirements. Customizing a Sheet Metal Shell allows adjustments in ventilation patterns, access panels, and surface treatments. This flexibility often leads to better system integration and lower maintenance costs over time.

By tailoring the enclosure to actual usage scenarios, I have noticed fewer retrofits and longer product lifecycles, which ultimately benefits both manufacturers and end users.

What Should You Consider Before Choosing a Sheet Metal Shell Supplier?

Beyond price, I always recommend evaluating production capability, quality control processes, and communication efficiency. A reliable partner understands that a Sheet Metal Shell is not just a metal box but a functional part of the final product.

- Engineering support during design stage

- Stable production capacity for scaling orders

- Clear documentation and inspection standards

Are You Ready to Upgrade Your Sheet Metal Shell Solution?

If you are looking to enhance protection, performance, and overall product value, investing in a well designed Sheet Metal Shell is a practical step forward. I encourage you to explore tailored solutions that align with your technical and commercial goals.

To discuss your project requirements or request detailed specifications, feel free to contact us today. Leave an inquiry and start building a more reliable enclosure solution with confidence.